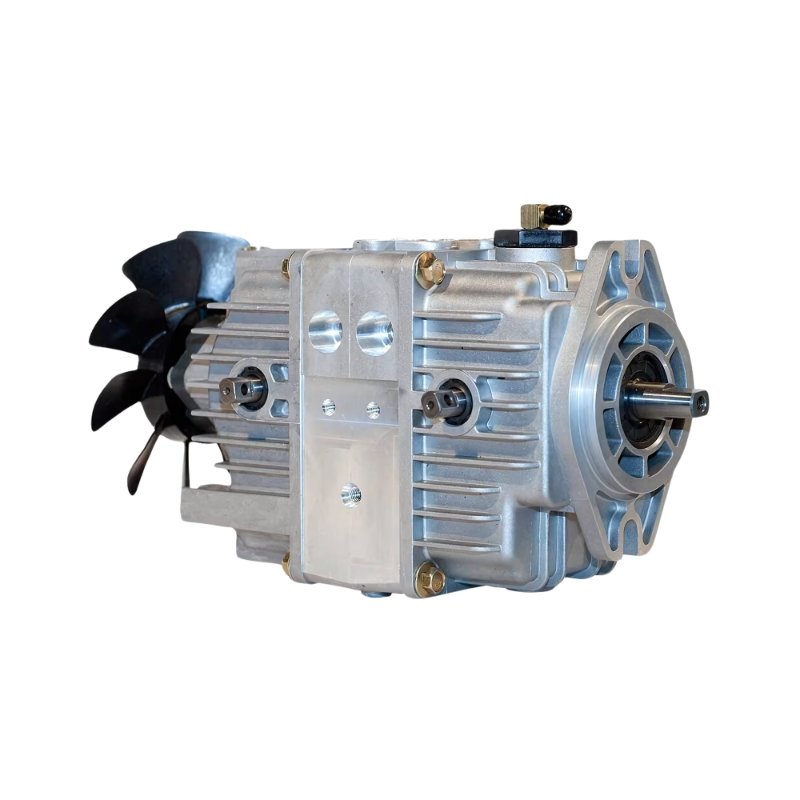

Parker Tandem Integrated Closed Loop Piston Pump – HP2 Series

Parker Tandem Integrated Closed Loop Piston Pump – HP2 Series

Parker HP2 Series is composed of two independently controlled over-center, piston pumps on a single drive shaft. At Rexton Hydraulic, we are leading supplier and service provider for Parker Tandem Integrated Closed Loop Piston Pump – HP2 Series within their entire frame/range.

- Series : Parker HP2 Series

- Axial Piston Variable Displacement Pump

- Model : 11.5 (0.70), 16.0 (0.98) .

- Nominal Pressure 90 Bar (Psi 1300)

- Maximum Pressure 180 Bar (Psi 2600)

- Input Speed Range 1800 to 3600 rpm

- Used in a wide range of applications – • Material Handling Equipment, • Forestry Equipment, • Agricultural Machinery, Mining, • Oil & Gas.

Share Product:

Parker Tandem Integrated Closed Loop Piston Pump (HP2 Series) is designed to reduce the number of parts required for a transmission system. HP1 and HP2 pumps considerably lower the cost and warranty risk related to hydraulic leakage. The HP2 Series is composed of two independently controlled, variable displacement, over-center piston pumps on a single input drive shaft.

Parker HP2 Series tandem pump system features a single input drive shaft, two 11.5 cc or 16.0 cc pumps, and an input speed range of 1800 to 3600 rpm. With a working pressure of 2600 psi, a 2.5-quart integral reservoir, shock and/or check valves, an integral filter, an integral system cooling fan, and a charge pump. These pumps have been a popular choice in various applications, including commercial turf equipment, trenchers, power buggies, snow handling equipment, small utility vehicles, and material handling equipment.

HP2 Series pumps are variable displacement closed loop, dual piston pumps that come with an integral system cooling fan and charge pump. These pumps are highly demanding for the hydraulic market and various industries such as turf equipment, material handling equipment, forestry equipment, mining, oil & gas, agricultural machinery, etc. where they are commonly used. Furthermore, they come with a filter, a small reservoir, and related valves. Those are needed to complete a dual-path hydrostatic propulsion system for running the hydraulic drive motor lines.

Technical Specifications

|

|

Technical Specifications

Technical Data

| Quick Reference Data Sheet | |||

| Displacement cc/rev (cu in/rev) |

Continuous Rating bar (PSI) |

Intermittent Rating bar (PSI) |

Flow @ 3600 RPM 100 psi, max angle |

| 11.5 (0.70) | 90 (1300) | 180 (2600) | 41.3 lpm (10.9 GPM) |

| 16.0 (0.98) | 90 (1300) | 180 (2600) | 57.9 lpm (15.3 GPM) |

Product Models

Coming Soon