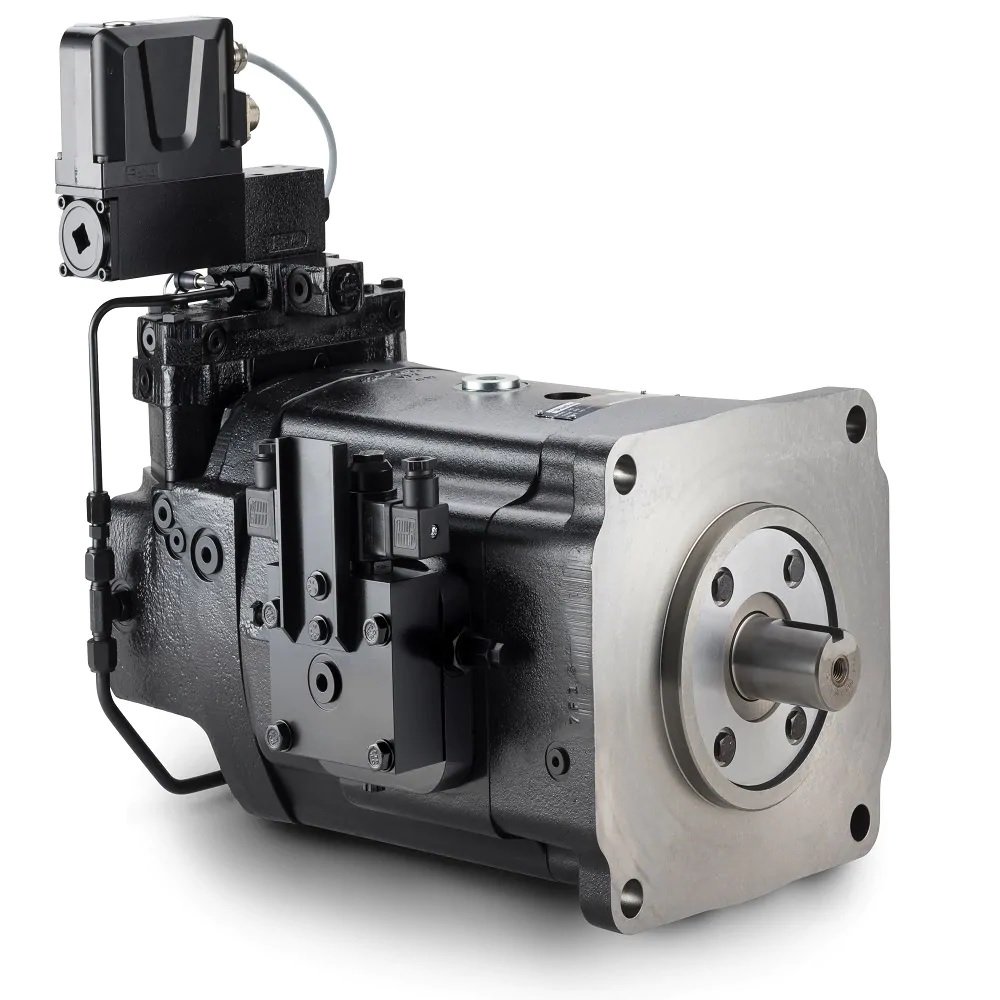

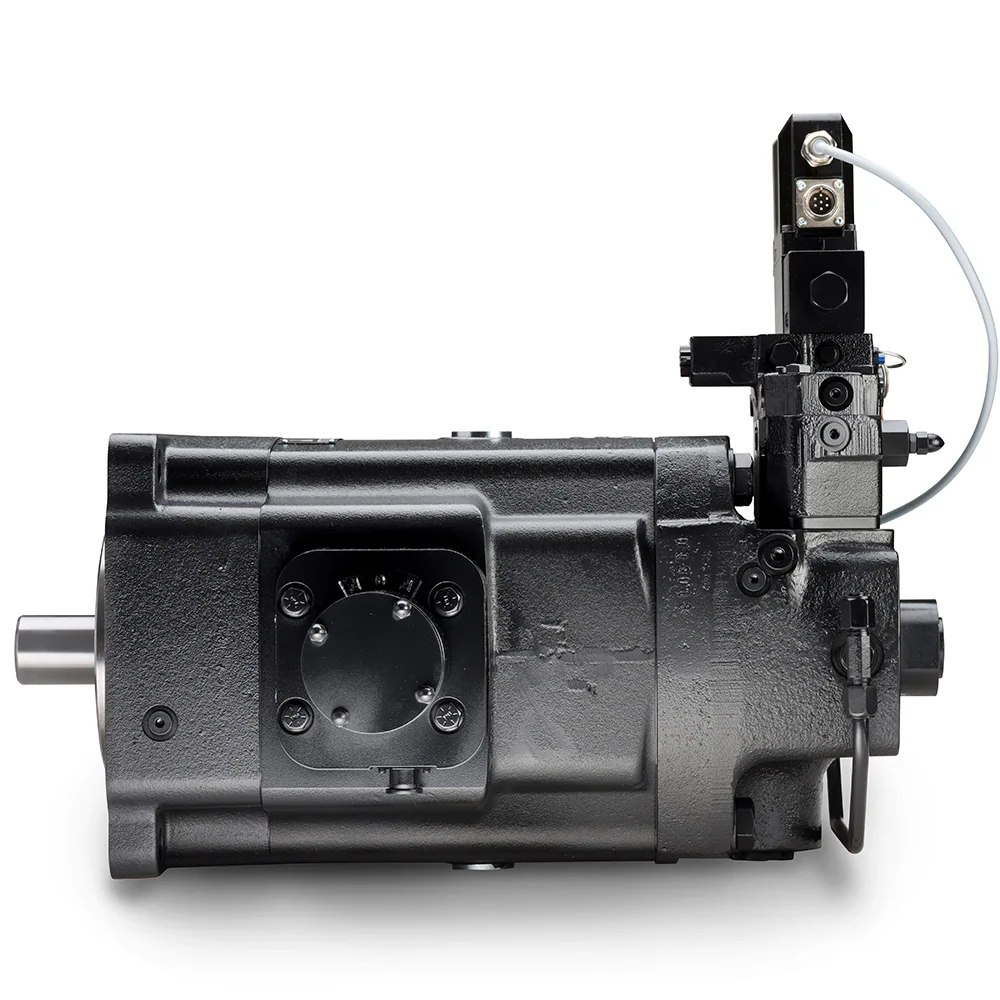

Parker Gold Cup Series Hydrostatic Pumps & Motors

Parker Gold Cup Series Hydrostatic Pumps & Motors

Parker GOLD CUP® Pumps & Motors ensure high performance in severe-duty applications. At Rexton Hydraulic, we are one of the leading suppliers and repair service providers of Parker Gold Cup Series Hydrostatic Pumps & Motors throughout their entire sizes/frames.

- Series : Parker Gold Cup Series

- Model Sizes : P6, P7, P8, P11, P14, P24, P30 (100-500 cc).

- Nominal Pressure 350 Bar (Psi 5000)

- Maximum Pressure 420 Bar (Psi 6000)

- Maximum Speed of 3,600 rpm

- Temperature Range of -40 to 203ºF (-40 to 95ºC)

- Used in a wide range of applications – • Mining, • Drilling, • Construction, • Material Handling, • Land & sea, • Marine, • Oil & Gas.

Share Product:

Parker Gold Cup Series Hydrostatic Pumps & Motors are designed with hydrostatic transmission and used in marine, drilling, and shredding applications. The GOLD CUP® pump and motors are constructed with many features, including an integral servo and replenishing pump, a hot oil shuttle, and a unique servo control system. These features work together to create a strong, independent package that can endure the most trying circumstances and carry on operating trouble-free for a very long time.

Parker GOLD CUP® Pumps & Motors are known for providing high performance and efficiency in heavy-duty applications. With a robust design, they operate to pressures up to 6,000 psi and speeds up to 3,600 rpm. Parker has taken over the Gold Cup brand from Denison since 2004. These pumps and motors are offered in multiple models/sizes (P6 | P7 | P8 | P11 | P14 | P24 | P30) and can be used in multiple machines.

Parker and Denison's combined experience in hydrostatic transmission applications is reflected in the heavy-duty GOLD CUP® pumps and motors. These pumps and motors are designed in a closed circuit design, which makes them perfect for bi-directional function and minimizes energy losses related to circuit valving. GOLD CUP® has a high power-to-weight ratio, a compact package, and flexibility in mounting and control options, which provides precise value-added benefits.

Technical Specifications

|

|

Technical Specifications

Technical Data

| Seires | Terms | P6 | P7 | P8 | P11 | P14 | P24 | P30 | |

| Displacement | Max. Displacement | in3/rev. | 6.00 | 7.25 | 8.00 | 11.00 | 14.00 | 24.60 | 30.60 |

| cm3/rev. | 98,3 | 118,8 | 131,1 | 180,3 | 229,5 | 403,2 | 501,5 | ||

| Pressure | Continuous | psi | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 |

| bar | 350 | 350 | 350 | 350 | 350 | 350 | 350 | ||

| Intermittent | psi | 60007) | 60007) | 5000 | 60007) | 60007) | 55001)7) | 55001)7) | |

| bar | 4207) | 4207) | 350 | 4207) | 4207) | 3701)7) | 3701)7) | ||

| Speed (Pump) | max.@ full stroke | rpm | 3000 | 3000 | 2700 | 2400 | 2400 | 21002) | 1800 |

| (Motor) | max.@ full stroke | rpm | 3000 | 3000 | 2700 | 2400 | 2400 | 21002) | 1800 |

| (Motor) | max.@ 50% stroke | rpm | 3600 | 3600 | 3000 | 2800 | 2800 | 21002) | 1800 |

| Mounting | Flange -2 bolt | SAE | 127-2 (C) | 127-2 (C) | 127-2 (C) | – | – | – | – |

| Flange -4 bolt (opt.on 6,7 & 8) |

SAE | 152-4 (D) | 152-4 (D) | 152-4 (D) | 165-4 (E) | 165-4 (E) | 177-4 (F) | 177-4 (F) | |

| Shaft – keyed | SAE | 32-1 (C) | 32-1 (C) | 32-1 (C) | 44-1 (E) | 44-1 (E) | 50-1 (F) | 50-1 (F) | |

| keyed | SAE | 44-1 (D) | 44-1 (D) | 44-1 (D) | – | – | – | – | |

| Shaft – splined | SAE | 32-4 (C) | 32-4 (C) | 32-4 (C) | 44-4 (E) | 44-4 (E) | 50-4(F) | 50-4(F) | |

| splined | SAE | 44-4 (D) | 44-4 (D) | 44-4 (D) | – | – | – | – | |

| Weight (Pump) less controls | Mass | lbs | 175-300 | 175-300 | 175-300 | 325-530 | 325-530 | 750-835 | 750-835 |

| kg. | 80-135 | 80-135 | 80-135 | 145-240 | 145-240 | 340-375 | 340-375 | ||

| Weight (Motor Fixed) | Mass | lbs | 110 | 110 | 110 | 250 | 250 | 510 | 600 |

| kg. | 50 | 50 | 50 | 110 | 110 | 230 | 270 | ||

| Weight (Motor Variable) less controls | Mass | lbs | 110 | 110 | 110 | 300 | 300 | 650 | 670 |

| kg. | 50 | 50 | 50 | 135 | 135 | 290 | 300 | ||

| Rotating inertia | lbs-in2 | 92 | 92 | 92 | 290 | 290 | 821 | 977 | |

| kg.m2 | 0,027 | 0,027 | 0,027 | 0,085 | 0,085 | 0,240 | 0,286 | ||

| Torque (Motor) theo.max. | per 100 psi | lbs-in | 95.5 | 115.4 | 127 | 175 | 222 | 392 | 487 |

| per 100 psi | Nm | 157 | 189 | 208 | 287 | 362 | 623 | 797 | |

| at 5000 psi | lbs-in | 4774 | 5769 | 6366 | 8750 | 11100 | 19576 | 24351 | |

| at 350 bar | Nm | 539,5 | 651,9 | 717 | 990 | 1250 | 2158 | 2752 | |

| Power (Motor) theo.max. | at 5000 psi, 350 bar | ||||||||

| per 100 rpm | hp | 7.6 | 9.2 | 10 | 13.8 | 17.6 | 31.1 | 38.6 | |

| kW | 5,7 | 6,8 | 7,5 | 10,3 | 13,1 | 23,1 | 28,8 | ||

| at 2000 rpm | hp | 151.5 | 183.1 | 201,5 | 277.8 | 353.5 | 621.3 | 695 | |

| kW | 113,0 | 136,6 | 152 | 207,0 | 263,7 | 463,5 | 518,2 | ||

| Torque (Motor) efficiency | approx.stalled | % theo. | 81 | 81 | 81 | 81 | 81 | 81 | 81 |

| running | % theo. | 93 | 93 | 93 | 93 | 93 | 93 | 93 | |

| Case pressure: max. | allowable continuous | psi | 75 | 75 | 75 | 75 | 75 | 75 | 75 |

| bar | 5,2 | 5,2 | 5,2 | 5,2 | 5,2 | 5,2 | 5,2 | ||

| intermittent | psi | 125 | 125 | 125 | 125 | 125 | 125 | 125 | |

| bar | 8,6 | 8,6 | 8,6 | 8,6 | 8,6 | 8,6 | 8,6 | ||

| (Not to exceed 25 psi,1,7 bar above inlet in open circuit units) | |||||||||

| Flow (Pump) theo.at max.displ. | @1500 rpm | gpm | 39 | 47 | 52 | 71 | 91 | 160 | 199 |

| lpm | 148 | 178 | 197 | 269 | 344 | 606 | 753 | ||

| @1800 rpm | gpm | 47 | 57 | 62 | 86 | 109 | 192 | 238 | |

| lpm | 178 | 216 | 235 | 326 | 413 | 727 | 901 | ||

| Displacement | (Internal aux.pump) | P6,7,8P,S,V | P11,14P,S | P11,14V | P24P | P24S3) | P30P | P30S3) | |

| in3/rev. | 1.07 | (2) 1.074) | 1.075) | 2.816) | 2.816) | 2.816) | 2.816) | ||

| cm3/rev. | 17,5 | (2) 17,5 | 17,5 | 46,1 | 46,1 | 46,1 | 46,1 | ||

| Flow (Internal aux.pump) | @1500 rpm | gpm | 6.9 | (2) 6.9 | 6.9 | 18.2 | 6.5 | 18.2 | 6.5 |

| lpm | 26,1 | (2) 26,1 | 26,1 | 68,9 | 24,6 | 69,1 | 24,6 | ||

| @1800 rpm | gpm | 8.3 | (2) 8.3 | 8.3 | 21.9 | 7.8 | 21.9 | 7.8 | |

| lpm | 31,4 | (2) 31,4 | 31,4 | 82,9 | 29,5 | 82,9 | 29,5 | ||

1) Max.pressure 5000 psi, (350 bar) for M24 and 30 series variable motors. Higher servo pressure may be required – consult Rexton Hydraulic .

2) On HF-1 fluids, 1800 RPM Max.on HF-0 fluids.

3) Internal cartridge provides servo flow and must be supercharged from external replenishing flow, from external auxiliary pump.

4) One servo cartridge and one replenishing cartridge.

5) Servo cartridge only.

6) Standard, other sizes available, see ordering code.

7) 10% of operation time, not exceeding 6 successive seconds.

Product Models

Coming Soon